Since our founding in 1981, our goals have remained unchanged: to apply supercritical fluids (SCF) to the development of innovative, industrially viable separation processes for extracting, purifying, recrystallizing, and fractionating a wide range of natural extracts, polymers and polymeric substrates, and specialty and fine chemicals.

Our mission is to replace traditional solvent extraction processes with supercritical CO2 technology and move the world towards a more environmentally conscious and cleaner future.

Phasex is staffed by a team of problem-solving chemical engineers, chemists, and technical specialists ready to apply SCFs to solve your particular technical and business opportunity. We provide a complete range of supercritical CO2 extraction services: feasibility studies, research and process development, toll processing, and technology licensing.

You don’t have to understand what’s behind all the technical information and science to know how and why we can help you, though you might be interested in what that translates to for your business, so here’s a rundown.

Long history of success. Phasex has a long history of success in developing new or improved products in the natural products extracts industry. In operation since 1981, we are pioneers in applying supercritical fluids for the extraction of many types of botanical and natural substrates to concentrate, and purifying various bioactives, flavors, and essential oils. Phasex has developed several high-efficiency CO2 extraction processes for concentrating active ingredients:

Superior quality. Supercritical CO2 extraction of botanical and biological substrates has produced superior quality, solvent-free extracts with increased concentration, and thus, higher value.

Complete services. Phasex offers a complete package of supercritical CO2 extraction services, including contract research, process/product development, toll manufacturing, and technology licensing.

Solely focused on SCF. With close to 40 years of success, we are the world’s most experienced supercritical CO2 extraction company solely focused on supercritical fluid technology for the development of improved processes and products.

Development and commercialization pioneer. Phasex pioneered many of the industrial applications in use today and has developed and commercialized many products.

Rapid optimization. We are known for our technical expertise and innovativeness, our versatile facility, and our ability to rapidly optimize and scale-up processes.

Renown expertise. Our experienced staff is regularly called upon to present at international symposia on supercritical fluid science and applications to share its renown expertise.

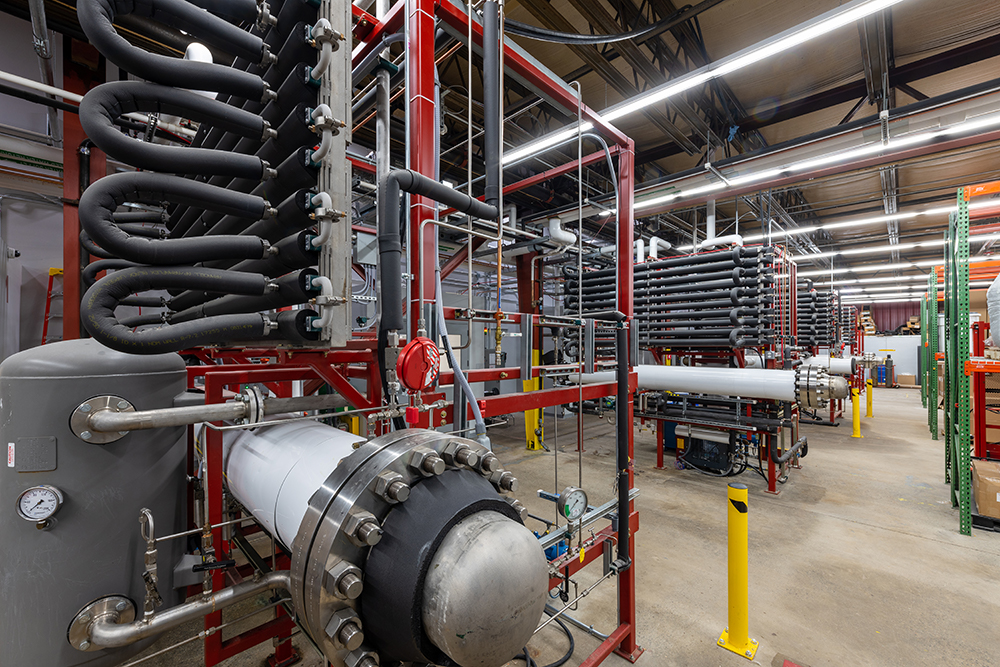

State-of-the-art facility and capacity. Our facility is the largest specialty materials processing facility in the U.S. and has the capacity to execute large nutraceuticals processing campaigns under food-grade compliant conditions.

Green chemistry. Supercritical fluid solvents are environmentally friendly and recyclable. There are NO hazardous waste streams, NO harsh organic chemicals or residues, and the gaseous solvent is recyclable.

Growing with you. We grow with our customers’ requirements, satisfying their needs at every point in the product evaluation sequence.

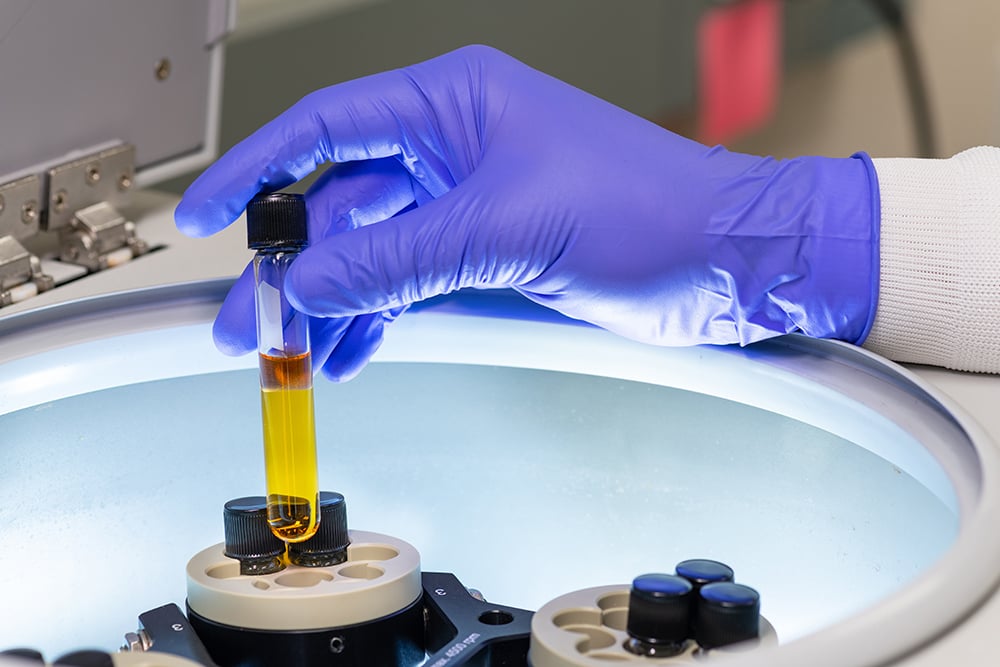

Take a look inside our extensive lab facility, where we serve a wide variety of industries by providing supercritical CO2 extraction. With four dedicated CO2 extraction plants, we develop processes at lab scale, then scale up to commercial level for clients who require more concentrated, purified active extracts using an environmentally clean process under certified GMP standards.

Our organic supercritical CO2 extraction methods are used to remediate, purify, recrystallize, and fractionate a wide range of natural extracts—herbs, foods, botanicals—polymers and polymeric substrates, and specialty and fine chemicals

Global Leader

As a global leader in sustainable and organic SCF CO2 extraction technology, we apply our unique proprietary expertise to create solutions with our customers that make a real difference in the world.

Having refined our expertise by performing thousands of extractions with different types of materials and approaching our 40th year of practicing this technology, we are known as “The Supercritical Fluids People.”

Green Chemistry

Supercritical CO2 is certainly a green solvent; by far, the most common supercritical fluid is gaseous carbon dioxide. By adjusting the processing pressure and temperature, the gas can act like a liquid solvent, but with selective dissolving powers. In the supercritical fluid phase, extraction concentration is carried out simply with changes in pressure, which results in a pure product fraction and a clean CO2 gas stream, which is completely recycled to the process.

Customer Commentary

Customers come to us because they find what they’ve been looking for: extracting without using traditional solvents.

What we often hear:

“You are truly changing the world.”

“No other toll processors can process our materials to this high quality.”

To help customers, the industries they supply, and the world become a bit cleaner and healthier, we choose not to work with harsher solvents. If you have an R&D problem that requires a harsher solvent to solve a problem on a smaller scale, we can do that, but we choose not to scale up this technology for use in our toll processing operations.

This enables:

We Wrote the Book!

Our founder literally wrote one of the seminal books on the use of supercritical fluid extraction. The technical innovations we’ve built help our customers create better products that are better for consumers.

We continue his legacy by developing:

Legacy Examples

You may not realize that you’ve already experienced some of our work. Here’s a taste of sa few of our projects:

And our story doesn’t end there. Through ongoing investment in research and development, we’re tackling a number of big challenges. In the last few years, some companies have approached us and asked if we could extract and eliminate the psychoactive components in whole plant hemp extracts. After exhaustive research, we’ve created a USDA-certified organic process that does not rely on any harsh solvents (the current industry practice) to purify CBD oil from industrial hemp, while removing residual THC to non-detectable levels.

Phasex is working with Fortune 100 companies to recycle plastics to virgin-like quality using SCF technology. We hope this work will transform how the world thinks of plastics in the near future. This development work is demonstrated in the promotional video below.

Other exciting activities at Phasex include:

We look forward to hearing from you as we move into the future.

125 Flagship Drive

North Andover, MA 01845