Many customers in natural product extracts industries partner with Phasex to:

We process a variety of natural product extracts that are used in diverse applications, some of which include:

Feasibility Studies —These are short, fast-response feasibility studies to demonstrate that processing with supercritical fluids can achieve your desired goals, both technically and economically.

Contract R&D—R&D projects are designed to achieve your goals—from creating a new product, improving an existing one, recovering a by-product, or other purposes.

Toll Processing—Our ability to process 1,000 to 100,000 kg quantities enables you to evaluate supercritical fluids for their specific needs without investing early stage and high-risk capital

Technology Licensing—Phasex can develop technology for supercritical separations to be carried out as a part of a company’s own manufacturing train.

Supercritical fluids are widely preferred for extraction, purification, recrystallization, and fractionation operations in many industries. The technology is used to process hundreds of millions of pounds of coffee, tea, and hops annually. Supercritical CO2 extraction is also gaining in herbal and botanical extracts, vitamins, and supplements industries—the fastest growing segments of the food industry today—as it is synonymous with the highest purity and quality.

Increasing scrutiny of organic solvents and the demand for improved nutraceutical and natural products have led to the evaluation of alternative and improved extraction methods. Supercritical CO2 concentrate active compounds: astaxanthin from a from microalgae, paclitaxel from yew needles, lycopene from tomato skins. We can fractionate EPA/DHA from fish oils and algae, helping nutraceutical companies to provide healthy fat ratios. Higher extraction efficiencies increase product concentration and yield, and most important, these superior quality extracts are free of solvent residues.

Supercritical fluid extraction is far more efficient than traditional solvent separation methods. Supercritical fluids are selective, thus providing the high purity and product concentrations. Additionally, there are no organic solvent residues in the extract or spent biomass. Extraction is efficient at modest operating temperatures—for example, at less than 50 degrees Celsius—thus ensuring maximum product stability and quality.

Dietary supplements are the fastest growing segment of the food industry, with the CRN Consumer Survey reporting 77% of Americans using dietary supplements—the highest usage to date (as of 2019). As well, the study identifies specific growth in botanicals and herbals. People look to the efficacy of supplements to augment their lifestyles and count on them to perform.

Supercritical CO2 extraction is the most efficient separation method for the dietary supplements market. It is capable of providing the highest purities and concentrations attainable. Typically, traditional organic solvent separation yields are high, but if heptane or methylene chloride solvents—for example—are used, there are almost assuredly trace solvents remaining in the extracts. Supercritical CO2 provides a USDA-certified organic process with the resulting concentrated extracts free of residual solvents in applications such as lycopene from tomato waste and phytosterols from cereal crops and odor removal from deep-ocean white fish powder.

Phasex’s proprietary extraction process helps maximize your product yields, minimize your contamination, and ensure the highest purity and quality with supercritical fluids

Organic solvents such as acetone and hexane have been used industrially for the extraction of astaxanthin from microalgae. The concentration of astaxanthin in these extracts, however, is limited because liquid solvents cannot differentiate between the lipids and the carotenoid.

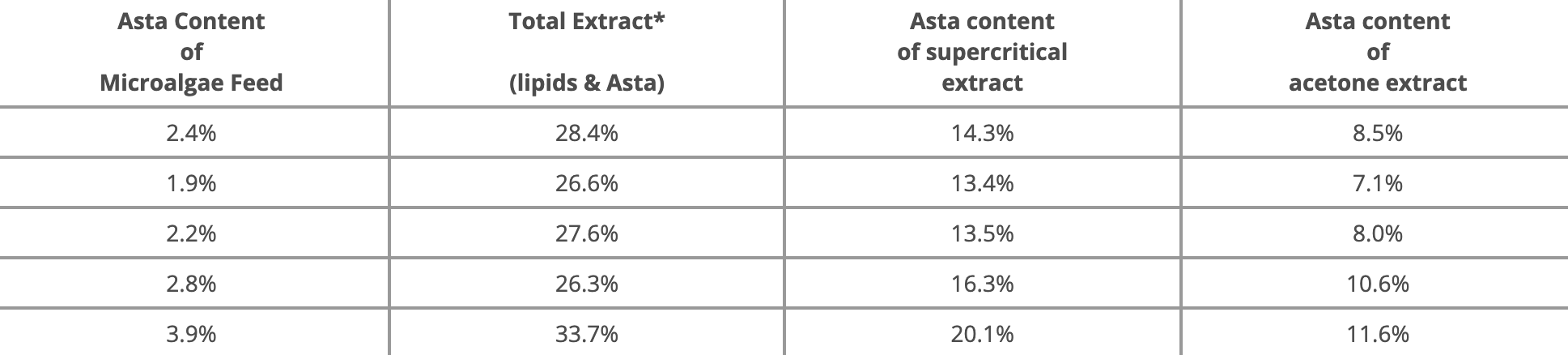

Microalgae, such as Haematococcus pluviales, contains between 2% to 4% (w/w) astaxanthin and an average 30% to 50% total extract of lipids, plus astaxanthin. Using organic solvents, the highest theoretical astaxanthin concentration achievable in the extract product is about 6.0% to 7.0%. Organic solvent extraction cannot produce a higher concentrate because the lipids and the astaxanthin are dissolved equally readily by acetone, for example. (The maximum astaxanthin concentration in the extract is calculated from the relation [% astaxanthin in algae] divided (by % extract/100).]

Much higher astaxanthin extract concentrations are achievable with supercritical fluids because of the ability to tailor their dissolving power (by tuning pressure). Lipids and carotenoids respond differently to supercritical CO2 and can be selectively separated, resulting in an extract high in the carotenoid

The photograph to the right shows a microalgae feedstock and a 14% astaxanthin concentrate. The table below gives some results from selected plant runs at Phasex using supercritical fluids compared to product typically obtained by acetone extraction.

Supercritical fluids are similarly applicable for the production of other concentrated carotenoid extract: lycopene, lutein, and zeaxanthin are typical of carotenoid compounds obtained from botanical substrates such as tomato, spinach, corn, and marigold.

Phasex can help you ensure maximum product stability, rendering the highest purity and quality for your ingredients.

Contact us now to get the Phasex advantage for your ingredients.

Beauty isn’t only skin deep, as it turns out—it has deep pockets, as well. According to Formula Botanica, “The global natural cosmetics market is estimated to be worth $36bn in 2019 and is now predicted to grow to $54bn by 2027.” Another telling statistic reported by the NPD Group in its release of the Women’s Facial Skincare Consumer Report is that “40% to 50% of women buying skin care products are actively choosing those that contain natural or organic ingredients.” As with all ingredients, purity, quality, and efficacy is of vital importance with skincare products. Our proprietary supercritical fluid CO2 extraction process is so exacting, the purity and potency are reflected in the final extracted ingredient. Essential oils for skin care from lei petals is one example of a process we have run.

As stated in an article of a lifestyle, health, and fitness magazine: On an annual level, Americans spend over $32 billion on dietary supplements such as vitamins, minerals, botanicals, and other healthy-living enhancers. Now legal in all 50 states, awareness and usage of hemp-derived CBD products is on the rise. In an article discussing upcoming CBD trends, CBD-infused products include “lattes, makeup, bedsheets, bath bombs, and even dog treats.”

To use in these applications—from topicals to ingestibles, for retail and recreational use—it is necessary to have the THC remediated out of the whole plant hemp so final products contain no more than 0.3% THC (full-spectrum), in keeping with the Food and Drug Administration regulation, 2020. Some applications require further broad-spectrum remediation, down to 0.0 % THC or less. Our proprietary food-grade CO2 process produces remediated ingredients with high actives with minors.

Convenience, portability, preservation, appearance, and flavor are among the reasons that the U.S. food and beverage industry expects the food additives market consumption levels to exceed 385 million tons by 2024. Interesting to note as well from this report is that “increasing difficulty in the supply chain owing to rise in logistics cost is likely to promoting the adoption of these materials to minimize the wastage and spoilage costs, thereby stimulating the global market growth. Rapid expansion of technology in the industry pertaining to consumer’s demand for healthy and organic food options will positively affect market growth.”

Which is exactly where and how Phasex’s team of experts and our food-grade supercritical fluid CO2 extraction process meets these growing global needs. It’s our proprietary CO2 process that was able to remove cholesterol from egg yolks for a customer, and extract carotenoids, such as lutein and astaxanthin, essential antioxidants that provide vital supplementation. Phospholipids from krill and kavalactones from kava root powder are other examples in this market.

The pet food ingredient market encompasses a host of segments—commercial manufacturers use ingredients in everything from cereals and fats to meats, additives, and flavor enhancers. As stated in a global forecast to 2025 study which projects that the pet food ingredient market will be worth $53.2 billion by 2025, the majority of these ingredients are by-products of food products manufactured for human consumption, providing economical solutions for pet food manufacturers

The SCF CO2 protocols we have established for F&B ingredients are aligned perfectly to serve the pet food ingredient industry requirements. Fats from flaxseed and DHA from algae oil are examples of SCF processes that have been carried out at Phasex.

Forecasts for the flavor concentrates market through 2027 are more than favorable for the rise and demand for natural “clean” ingredients. Quick nutrition in the form of protein bars and fortified smoothies are becoming meal choices in health-centric, on-the-go lifestyles. This is of particular note in a summary of the report:

There has been rise in the consumption of natural flavor concentrates in the food industry, owing to the increasing health awareness among people around the world. People are shifting more towards natural and organic food products in their daily diet. Therefore, this shift of the population towards natural products is expected to boost the demand for natural flavor concentrate in the food industry during the forecast period. Manufacturers are also planning to develop more innovative and new natural flavor concentrates with various flavor and exotic taste that has no harm to the human health. They have adopted new & advanced technologies such as supercritical carbon dioxide extraction, solid-liquid extraction (SLE), supercritical fluid extraction, and many more. Hence, this innovation in the flavor concentrates help to drive the global market growth. Along with the above-mentioned drivers, there are some restrains in the flavor concentrates market that are likely to restrict its growth in the future such as presence of large number of players who are high performers in the market, which create a competitive restraint for the new players to enter into the market.

Having literally written the book on supercritical fluid extraction, combined with almost 40 years of deep legacy knowledge and expertise, Phasex is, indeed, a high performer in this market, and is positioned to help customers grow and perform exceptionally well. Curcuminoids from turmeric, glycosides from ginseng, and natural phenolics from echinacea powder are examples of SC CO2 extracts that can be achieved at Phasex.

michele.mersicano@robertet.com

125 Flagship Drive

North Andover, MA 01845