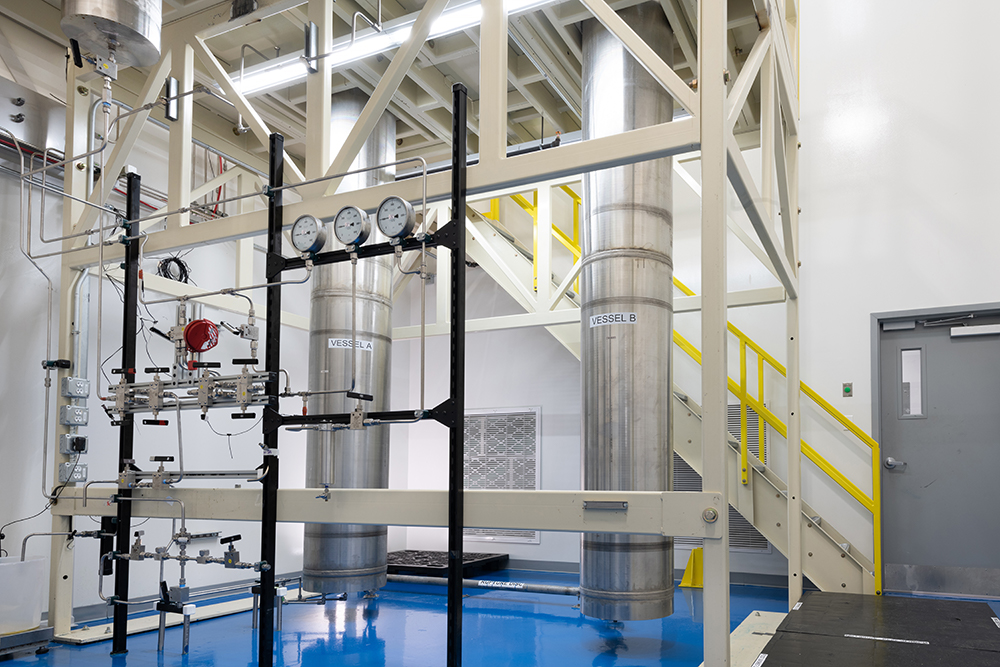

Extracting, separating, purifying, crystalizing are all outcomes that customers rely on Phasex to perform, using our proprietary supercritical fluid CO2 process for a variety of materials used in diverse application across a host of markets. Phasex is the world’s most experienced company whose business is solely the application of supercritical fluid technology to the development of improved processes and products.

Phasex pioneered many of the industrial applications in use today and has developed and commercialized many products, and is renowned for our:

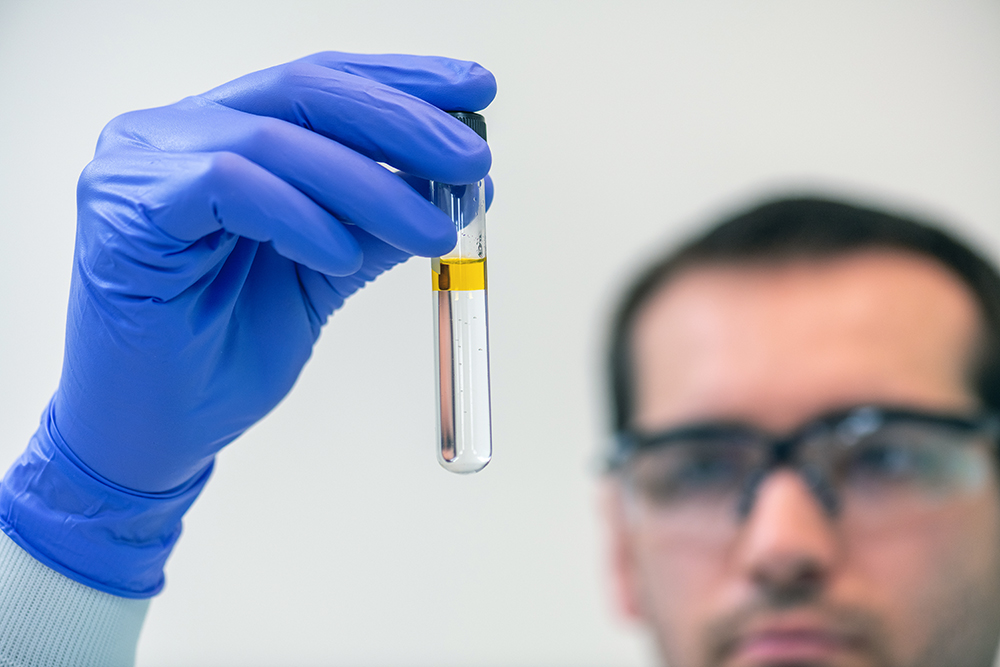

Supercritical fluids provide processing capabilities not available with other purification and extraction methods. Phasex has developed processes for purifying heat labile compounds, where traditional distillation methods have failed, and extracting active components from botanical substrates with no residual solvent levels in the final product. Our selective extraction and recrystallization using supercritical fluids has benefited the pharmaceutical industry with increased yield and solvent-free products.

Phasex’s proprietary food-grade supercritical CO2 extraction process helps:

Integrating 75 years of combined experience in the application of supercritical fluids, Phasex continues to excel in developing new market opportunities for the technology. We’ve been involved, at one time or another, in nearly every industry. Our activities still reach a diversity of markets and will continue to evolve to reflect changes in industrial climate.

Successful customer processing includes:

It’s important to note that we don’t provide ingredients for customers—we process it for you. In some instances, we might be able to source it, but we don’t supply it.

We apply the technology to the markets below—click on the links for more application details within each market:

Feasibility Studies —These are short, fast-response feasibility studies to demonstrate that processing with supercritical fluids can achieve your desired goals, both technically and economically.

Contract R&D—R&D projects are designed to achieve your goals—from creating a new product, improving an existing one, recovering a by-product, or other purposes.

Toll Processing—Our ability to process 1,000 to 100,000 kg quantities enables you to evaluate supercritical fluids for their specific needs without investing early stage and high-risk capital

Technology Licensing—Phasex can develop technology for supercritical separations to be carried out as a part of a company’s own manufacturing train.

michele.mersicano@robertet.com

125 Flagship Drive

North Andover, MA 01845